Best Lock Company Copies By Robert Dix

reprinted courtesy of the author, Robert Dix. Originally appeared in the Journal of the American Lock Collectors Association. Robert Dix ©2005

In the last issue of the JOURNAL OF LOCK COLLECTING I explored the mystique Best locks had at one time and how that mystique eroded away over the years. At the same time Frank Best was selling his locks there were other companies that either copied Best or licensed Best designs. As with many events from the past it is difficult to determine

exactly what these companies were doing. Either they encroached on Best’s patents and Best stopped them before large quantities of bogus locks were made or they made their products with the help of Best.

A unique feature of Best locks is their notched tip which is actually the stop. Therefore, all Best lock spacing is referenced from this tip stop. Several lock companies used this tip stop in their design.

Best apparently allowed this design, therefore they might have been involved in competitor’s designs; perhaps through licensing (figure 1). This tip stop is a good indicator of a possible Best copy.

The most obvious company that was the largest and seemed to survive the longest was

UNIT LOCK COMPANY.

Very little is known about Unit Locks. They were probably made in Tulsa, Oklahoma in

the late 1920’s and early 1930’s. They had an interchangeable core, but it did not have a control key. To remove the core one must remove a screw, accessible through the shackle hole.

Unit keys had the exact dimensions of Best. This included the root depths of a Best A2 system. The root depth is the depth of each cut measured from the back of the key to the bottom of the bitting. These keys even had the same bow shape (figures 2 and 3).

Even specific designs were present on the Unit keys. Best keys always had a border of stars. Unit keys also had these stars on the rear of their keys only. The area where Best stamped their blind key code is occupied by a direct digit code on the Unit keys. Actually there wasn’t an area to stamp a blind code on the Unit keys, just a direct code. This may indicate that Best was concerned with key records and key control and Unit wasn’t.

By studying the Unit pin tumblers with dial calipers, one quickly realizes the pins are identical. Unit pins can be used in Best cores and vice-versa.

Figure 4 is a factory cut away of a large size Unit padlock. Except for the key and pin similarities, there is little else common.

Unit lock does have a removable core, but it is round. Note that the core shown in figure 5 has Bakelite caps exactly like Best used in the early days.

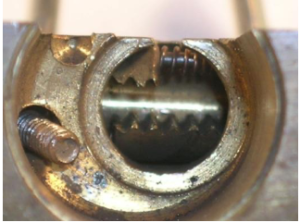

Figure 6 is looking down the hole where the core mounted. Note the retaining screw on the

left and the gear teeth on the two bolts. This is a unique feature and makes raking the lock open almost impossible. Original Best locks could be very easily raked open.

Figure 6 shows the core removed and the gear-drive throw member. If the gear throw member comes out with the core you have some work ahead synchronizing the gear on the two bolts with the member. The lock is designed to be closed automatically. This is accomplished by a lost motion action at the retaining screw teeth end of the throw member. Also, note the

retaining screw at the left and the core locating hole just above it (there are actually two).

Figure 8 has the core removed and shows the geared throw member. Also demonstrated is the fact the lock is not easily serviceable.

Some of the unique construction of the Unit lock can be seen in figure 10. Note the brass plug that has been inserted in the bottom of the shackle hole. This plug is soldered in! The plug on the side of the lock that seals the hole where the bolts are inserted is also soldered.

The plug is necessary in the case bottom because a retaining ring must be installed at the end of the shackle. This is an example of poor engineering. The lock is almost unserviceable. I personally have only seen one keyway used with Unit locks. It is very similar to the Best “A” but will not fit a Best “A”. Best does not have an exact match for the Unit keyway.

My theory about these locks is Unit Lock Co. could not or could not afford to make the cylinder and keys. They contracted with Best to make these components. Naturally Best used pins and keys that they were custom to using. This approach where the lock body was made by one company and the cylinder/keys were made for them is common. In the article on High Security Locks it was noted that almost all US high security locks used foreign cylinders.

I have not been able to find any Unit Lock patents. Perhaps they never filed any. There have been two sizes of the locks observed. The small lock measures 1.5″w X 2.75″h X 0.875″d. The large lock measures 2.0″w x 3.0″h x 0.875″d. There have also two different case manufacturing processes used. Some cases are cast and others extruded. suspect that the cast cases were made first and the extruded later. There are two different core lengths available; a five pin and a 6 pin (figure 9)

Unit Lock company had large commercial customers because they had some great logos. I have logos which are cast but none stamped.

Of the three I have, two are oil companies. It does make sense of oil companies to use Unit locks because they were located in Oklahoma. Figure 13 shows three logo locks.

The first logo lock is Indian Territory Illuminating Oil. The center one is CONOCO and the one the left is unknown. The initials are WPA Co.

I do not have any information on Unit Lock, when it started, ended or how large it was. If anyone has information I would greatly appreciate it.

Read Lock Company

The Read Lock Company is a real mystery. Read is actually more of a mystery than Unit Lock. All that I have from the Read Lock is a cylinder and an original key.

Read uses the Best “A” keyway. The key is exactly like a Best old short blank (figure 14).

In figure 13 note the Best stars and the stop at the tip of the key.

In figure 14 the back of the Read key also shows the Best stars and a direct digit bitting code. I used a Best Key Combinator and cut a perfect operating key for the cylinder. Just as with Unit, Read uses Best pins and Bakelite caps.

The Read cylinder is larger than the standard mortise cylinders. It measures 1.75″w 1.25″d. A standard mortise cylinder needs a 1.09375″ threaded hole. The Read needs a 1.25″ hole. The cylinder has a free rotating steel ring preventing a wrench attack. The cylinder seems to be high security for those times.

The Read is a very heavy well made cylinder. The drive pins shown in figure 17 are usually associated with a large, direct driven bolt. These pins fit into a rack gear which usually needs a 360° turn to extend or retract.

Perhaps I will find the complete lock someday. It should be heavy and quite impressive. The complete lock might reveal some patent numbers or dates. The Read cylinder was designed to prevent physical attack. There is a small threaded hole at the rear of the cylinder which was probably used to secure it. This cylinder was designed to fit 0.5″ thick material.

I feel that Read, like Unit, had the help of Best Lock Co. in some way. There could be records at the Best factory that might shed some light on these mystery Best copies.

Have something Best Lock related we missed? Please help us fill in any missing details.

SubmitA site dedicated to the history of the Best Lock Corporation Interchangeable Core Padlock.

Leave a Reply